Inch Tolerances

Definitions

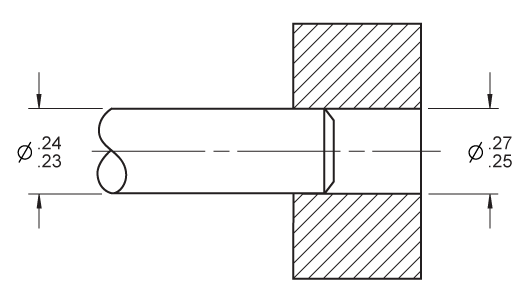

Limits: The limits are the maximum and minimum size that the part is allowed to be.

Basic Size: The basic size is the size from which the limits are calculated. It is common for both the hole and the shaft and is usually the closest fraction.

Tolerance: The tolerance is the total amount a specific dimension is permitted to vary.

Maximum Material Condition (MMC): The MMC is the size of the part when it consists of the most material.

Least Material Condition (LMC): The LMC is the size of the part when it consists of the least material.

Maximum Clearance: The maximum amount of space that can exist between the hole and the shaft.

Max. Clearance = LMChole – LMCshaft

Minimum Clearance (Allowance): The minimum amount of space that can exist between the hole and the shaft.

Min. Clearance = MMChole – MMCshaft