Dimensioning Rules

Functional dimensioning

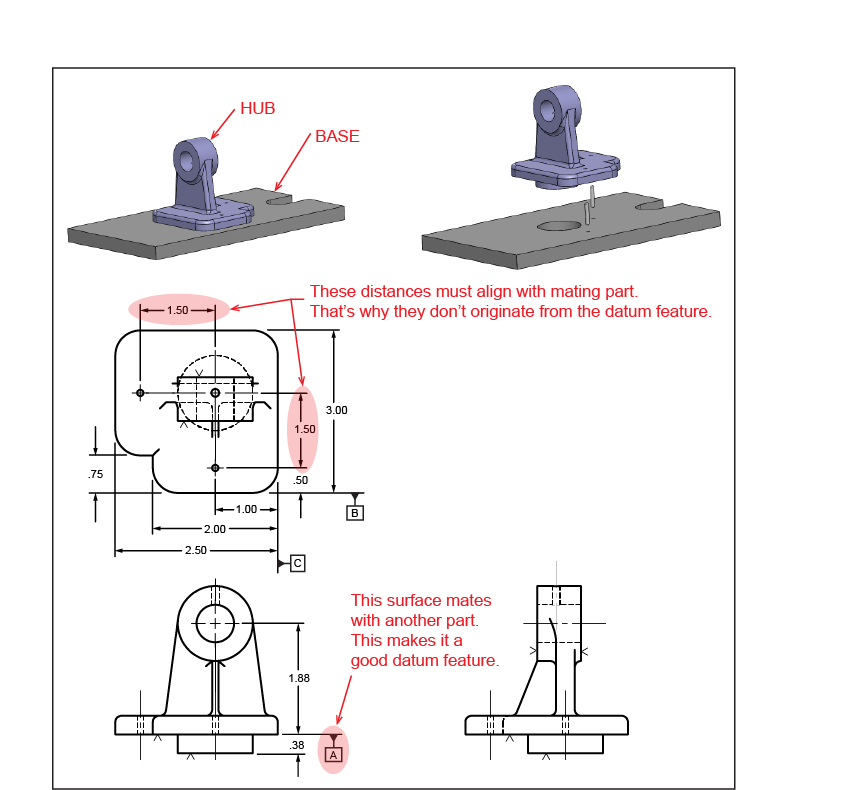

Rule 9) Dimensions imply function. When reading a print, the dimensions give you clues to the part’s function and mating relationships.

Choose your dimensions based on the function of your part.

Datum Planes / Datum Features

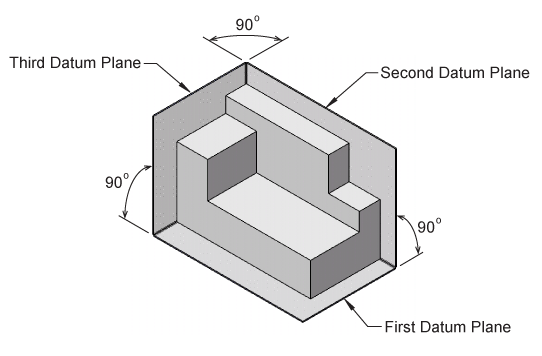

Consider three mutually perpendicular datum planes. These planes are imaginary and theoretically exact. Now, consider a part that touches all three datum planes. The surfaces of the part that touch the datum planes are called datum features.

Most of the time, features on a part are located with respect to a datum feature.

How do we choose which surface will be a datum feature?

Good datum features are:

- functionally important surfaces

- mating surfaces

- big enough to permit its use in manufacturing the part

In a classroom/learning setting, do we always know the function of the part? No. We need to make an educated guess as to the function of the part.

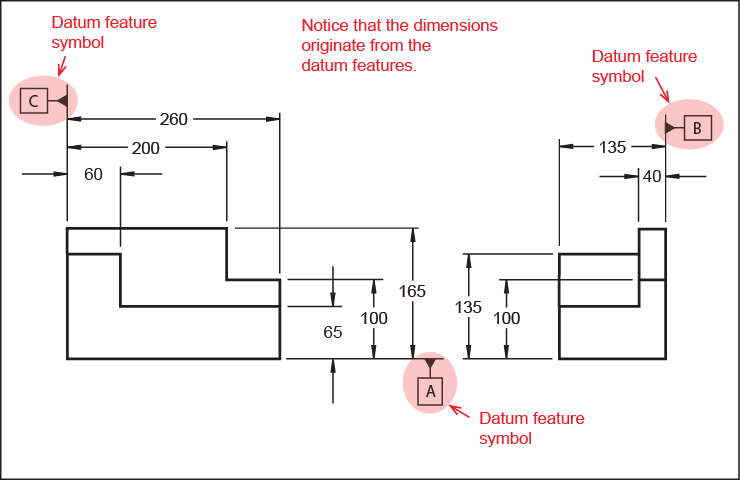

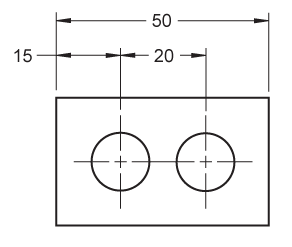

Locating Features Using Datums

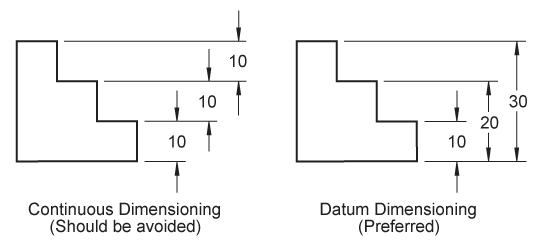

- Datum dimensioning is preferred over continuous dimensioning.

- Dimensions should be given between points or surfaces that have a functional relation to each other such as slots, mating hole patterns, etc...

Why is the distance between the two holes functionally important? If the hole pattern mates with 2 pins or bolts, the distance between the holes is more important than the distance from the edge to the second hole.