Metric Tolerances

Metric Tolerance Definitions

Limits, Basic Size, Tolerance, MMC and LMC have the same definition as in the inch tolerance section.

Upper deviation: The upper deviation is the difference between the basic size and the permitted maximum size of the part.

UD = |basic size – Dmax|

Lower deviation: The lower deviation is the difference between the basic size and the minimum permitted size of the part.

LD = |basic size – Dmin|

Fundamental deviation: The fundamental deviation is the closest deviation to the basic size. The fundamental deviation is the smaller of the UD and the LD. A letter in the fit specification represents the fundamental deviation.

Ex: Metric Fit = H11/c11

International tolerance grade number (IT#): The IT#’s are a set of tolerances that vary according to the basic size and provide the same relative level of accuracy within a given grade. The number in the fit specification represents the IT#. A smaller number provides a smaller tolerance.

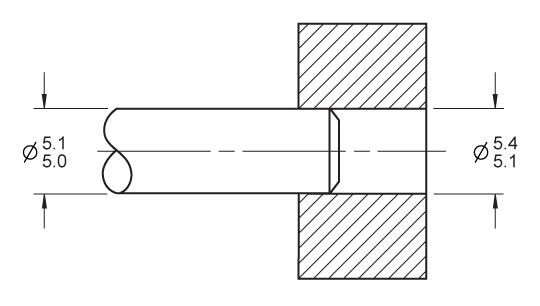

Tolerance zone: The fundamental deviation in combination with the IT# defines the tolerance zone. The IT# establishes the magnitude of the tolerance zone or the amount that the dimension can vary. The fundamental deviation establishes the position of the tolerance zone with respect to the basic size.

Previous Next