Ex: Milling Jack assembly tolerances

In this exercise we will practice using the standard to determine limits for a real assembly.

You will need the ANSI limits and fit tables found in the Appendix of your book to complete this exercise.

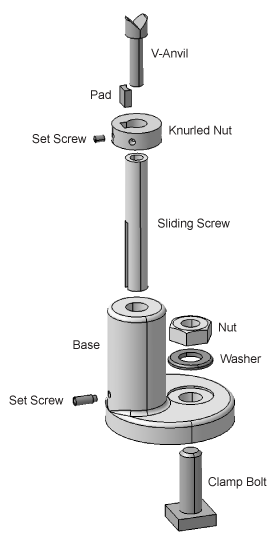

Consider the Milling Jack assembly shown. Notice that there are many parts that fit into or around other parts. Each of these parts are toleranced to ensure proper fit and function.

The shaft of the V-Anvil fits into the hole of the Sliding Screw with a RC4 fit. The basic size is .375 (3/8). Determine the limits for both parts.

| Limit - Min | Limit - Max | Check | |

|---|---|---|---|

| Shaft | |||

| Hole |

The shaft of the Sliding Screw fits into the hole of the Base with a RC5 fit. The basic size is .625 (5/8). Determine the limits for both parts.

| Limit - Min | Limit - Max | Check | |

|---|---|---|---|

| Shaft | |||

| Hole |