Dimensioning Rules

Manufacturing

Dimensions influence manufacturing. Dimension placement and dimension text influences the manufacturing process used to make the part. However, manufacturing processes should not be specifically stated on a drawing. Choose dimensions based on function first then manufacturing.

Rule 5) Don’t specify manufacturing processes with your dimension. For example, words such as “DRILL”, “REAM”, and “PUNCH” should not be placed with the feature size.

Rule 6) Parts identified by gage or code numbers are dimensioned using their actual decimal size.

Rule 7) All dimensions are applicable at 20oC unless otherwise specified.

Rule 8) Part sizes prior to processing may be specified on a drawing. These dimensions are identified using the note “NONMANDATORY (MFG DATA)”.

- Decimal dimensions should be used for all machining dimensions. You may encounter a drawing that specifies standard drills, broaches, and the like by size. For drill sizes that are given by number or letter, a decimal size should also be given.

- On drawings where all the dimensions are either in inches or millimeters the following note should be used. UNLESS OTHERWISE SPECIFIED, ALL DIMENSION ARE IN MILLIMETERS (or INCHES). If an inch dimension is given on a millimeter drawing or visa versa, the abbreviations IN or mm should be placed after the dimension value.

- Metric dimensions are given in ‘mm’ and to 0 or 1 decimal place (e.g. 10, 10.2). When the dimension is less than a millimeter, a zero should precede the decimal point (e.g. 0.5).

- English dimensions are given in ‘inches’ and to 2 decimal places (e.g. 1.25). A zero is not shown before the decimal point for values less than one inch (e.g. .75).

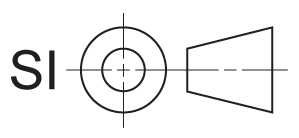

- Metric 3rd angle drawings are designated by the SI symbol.

Dimension Accuracy

There is no such thing as an "exact" measurement. Every dimension has an implied or stated tolerance associated with it. A tolerance is the amount a dimension is allowed to vary.

Rounding off

The more accurate the dimension the more expensive it is to manufacture. To cut costs it is necessary to round off fractional dimensions.

How do we round off?

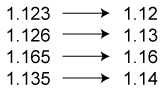

Let’s round off to the second decimal place. If the third decimal place number is:

- less than 5, we truncate after the second decimal place.

- greater than 5, we round up and increase the second decimal place number by 1.

- exactly 5, whether or not we round up depends on if the second decimal place number is odd or even. If it is odd, we round up and if it is even, it is kept the same.